Boeing EWING

February 2021 ~ 4 Person Team

Overview

The Boeing Company's Engineering Workshop of Industry, Networking, and Guidance (EWING) invited undergraduate engineering students to work with a team and to complete a real-life engineering design challenge on a Boeing airplane interior.

I worked with a team of 3 other undergraduate engineers from different schools to design an aircraft interior of a Boeing 737 Max-7 for a specific customer, following customer needs, aircraft manufacturing limitations, and all safety requirements from FAA and other regulatory agencies

Objectives

- The number of available seats must equal or exceed the number of expected passengers.

- Doors must have a 36" x 36" unobstructed area.

- All walkways must be at least 24" wide.

- Average floor loading must be less than 15 lb/ft^2.

- Center-of-gravity must be balanced.

- Power consumption cannot exceed 5kW.

- Fuel consumption cannot exceed 840 gallons per hour.

- Total budget of $10 million.

- Customer profile: upper-class family or groups of friends; party of 6 with interests in relaxing and multimedia entertainment.

Skills

Data Analysis: Google Sheets

Other skills: collaborative creativity, public presentation, teamwork across backgrounds

The Infinity Plane

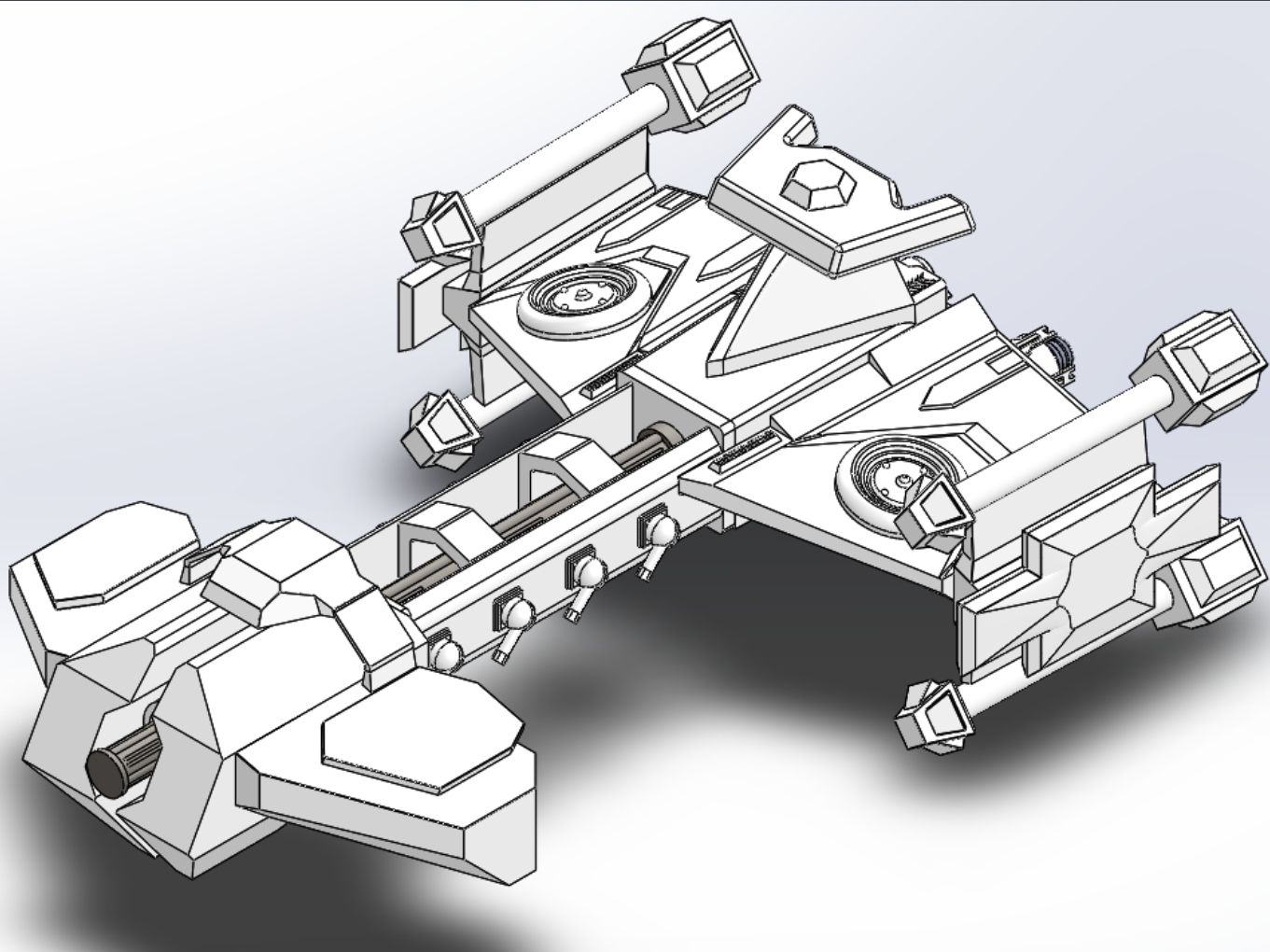

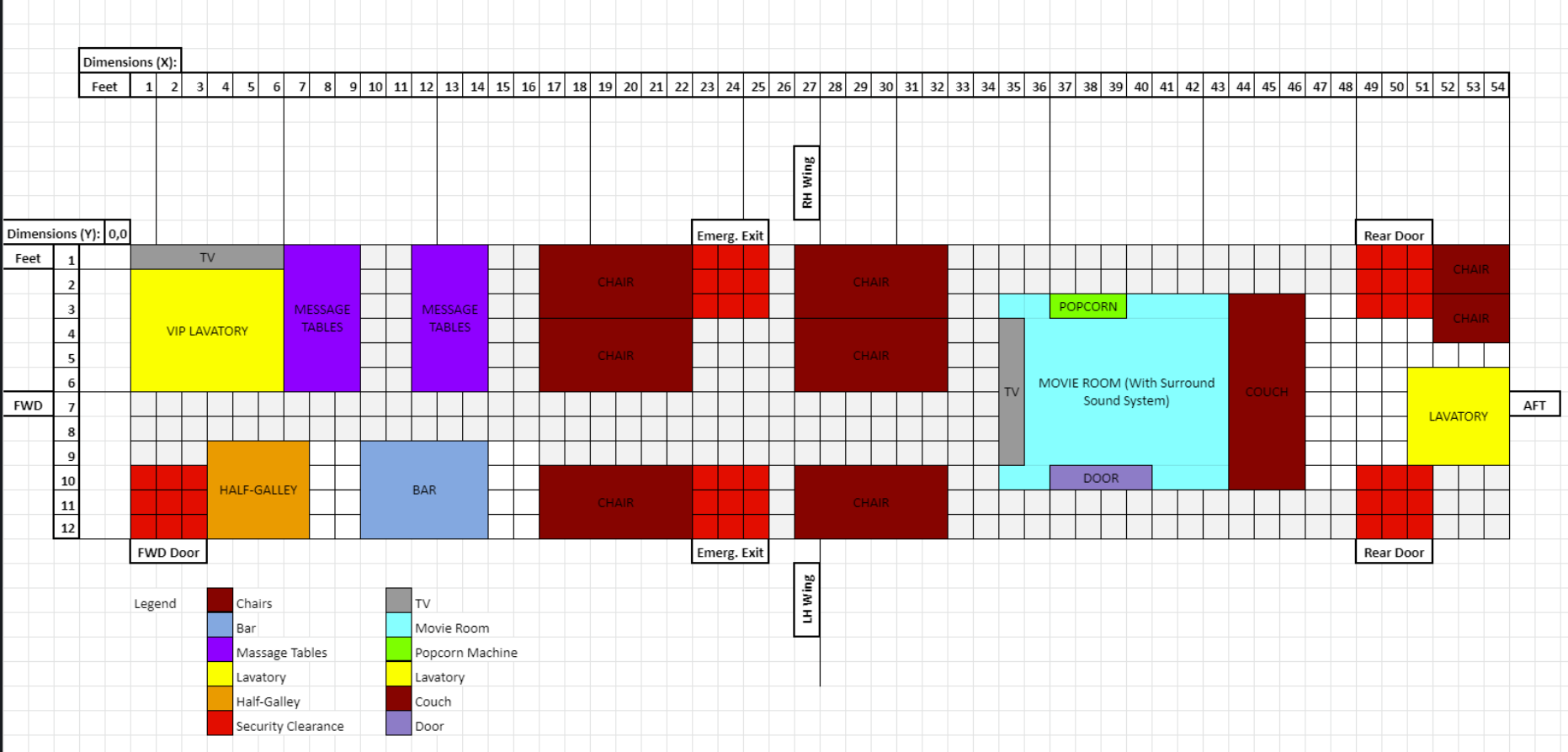

LOPA (Layup of Passenger Accommodation)

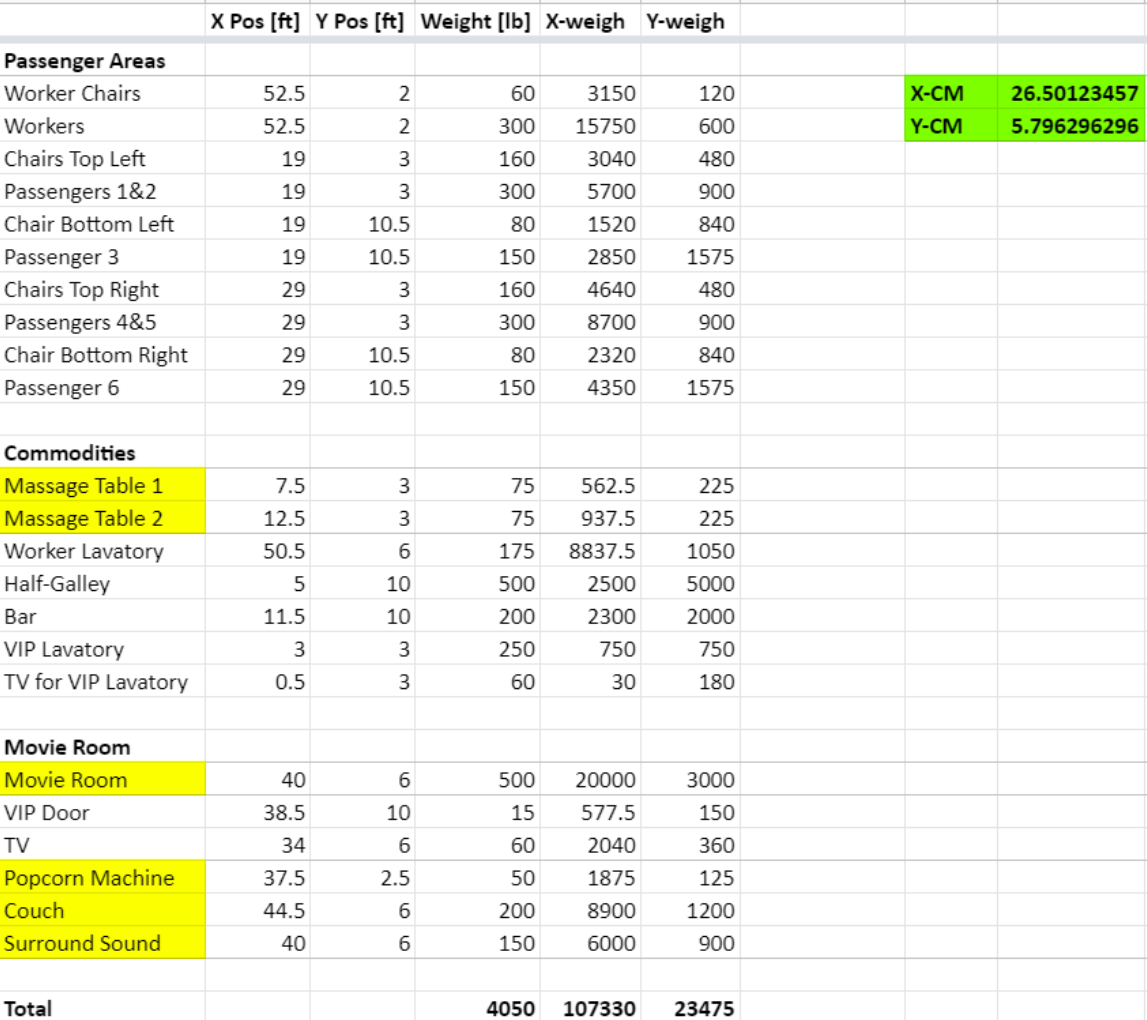

Center of Mass Calculations

Expected Center of Mass

Statistics

- Floor Loading = 6.25 lb/ft2 (sum of the weight of each item divided by total floor area)

- Center of Mass = 26.50 ft from the fuselage tip, 5.80 ft from the right side of the fuselage (sum of the weight of each item multiplied by their x or y location, divided by the total weight)

- Efficiency = 1 (well balanced center of gravity)

- Power Consumption = 2340 Watts (sum of all power draw items)

- Fuel Consumption = 800 gal/hr ((750 gal*efficiency)/(100%-(floor loading/15 lbs ft2)*15%)hr)

- Total Estimated Costs (for 10 years of operation) = $8,675,000

Outcomes

- 1st place peer nomination for best creativity, 1st place peer nomination for best presentation, and 1st place award by judges out of 5 teams.

- Learned to use Excel Sheets to simplify calculations and to ensure all the requirements are met.

- Learned to collaboratively navigated individual creative processes to design this final product.

- Experienced the complexity of meeting safety requirements: introduction of new equipment and furniture leads to corresponding safety needs.

- Discovered the design side of engineering outside of aerodynamics, structural analysis, or thermodynamics.