Bruin Underwater Robotics (BUR)

2021 - 2022: Autonomous Underwater Vehicle (AUV) Co-Lead

Overview

The Autonomous Underwater Vehicle (AUV) team was created to transition the BUR team to the RoboSub AUV Competition. We focused on developing three key elements: underwater controls algorithm, computer vision system, and an environmental simulator. We hope to fully participate in the RoboSub AUV Competition in the Spring of 2023.

Objectives

Underwater Controls Algorithm: an overarching algorithm shall describe the steps required to take the AUV from taking data from sensors to autonomously making decisions, then to executing movements or actuators. A list of concepts or knowledge points required for AUV operation shall be listed for current and future investigation.

Computer Vision System: an onboard processing unit shall be able to identify objects in its vicinity as well as localize its own location. The computer vision system shall be operated on as simple equipment as possible to reduce complexity.

Environmental Simulator: the environmental shall create a virtual physics environment to test software and hardware updates without physical testing. This requires a realistic physics engine, light/imaging engine, and a terrain engine. The simulator shall allow easy imports of CAD models and controls algorithms

Skills

Programming: MATLAB/Simulink

Management: Gantt chart, lead meetings, task delegation

Other Skills: Derived requirements, design report study, ROS (Robotic Operating System) Architecture, A* (pathfinding algorithms), YOLOv5 (Computer Vision Algorithm)

Key Tasks

In addition to leading weekly design meetings with 10 engineers across mechanical, electrical, and computer science fields, I led the progress to begin the development of an AUV system.

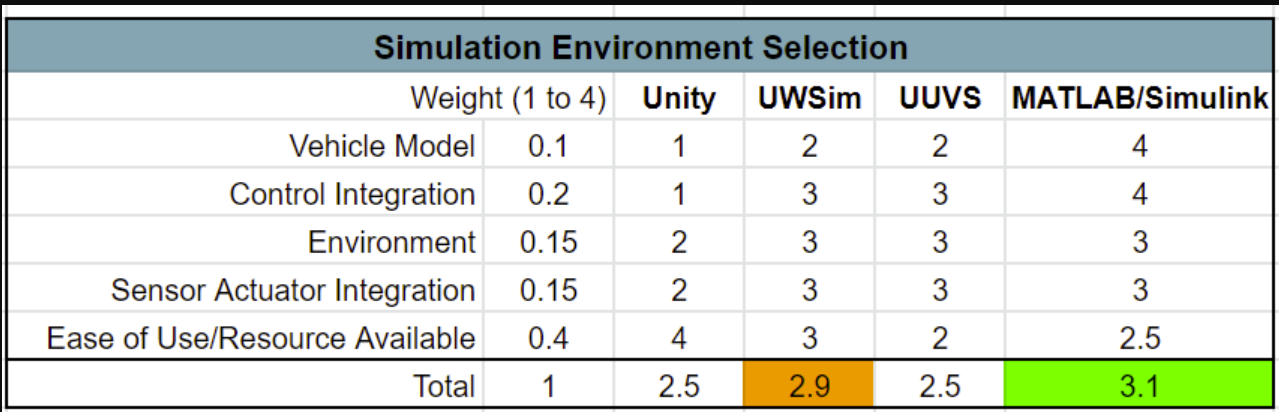

Figure-of-Merit Study to Select Simulation Environment

Sample Underwater Environment

Simulated Objects in Environment

- Directed a design report study of existing AUVs and listed key requirements for underwater autonomous operations. These requirements helped our team drive our key goals for this year.

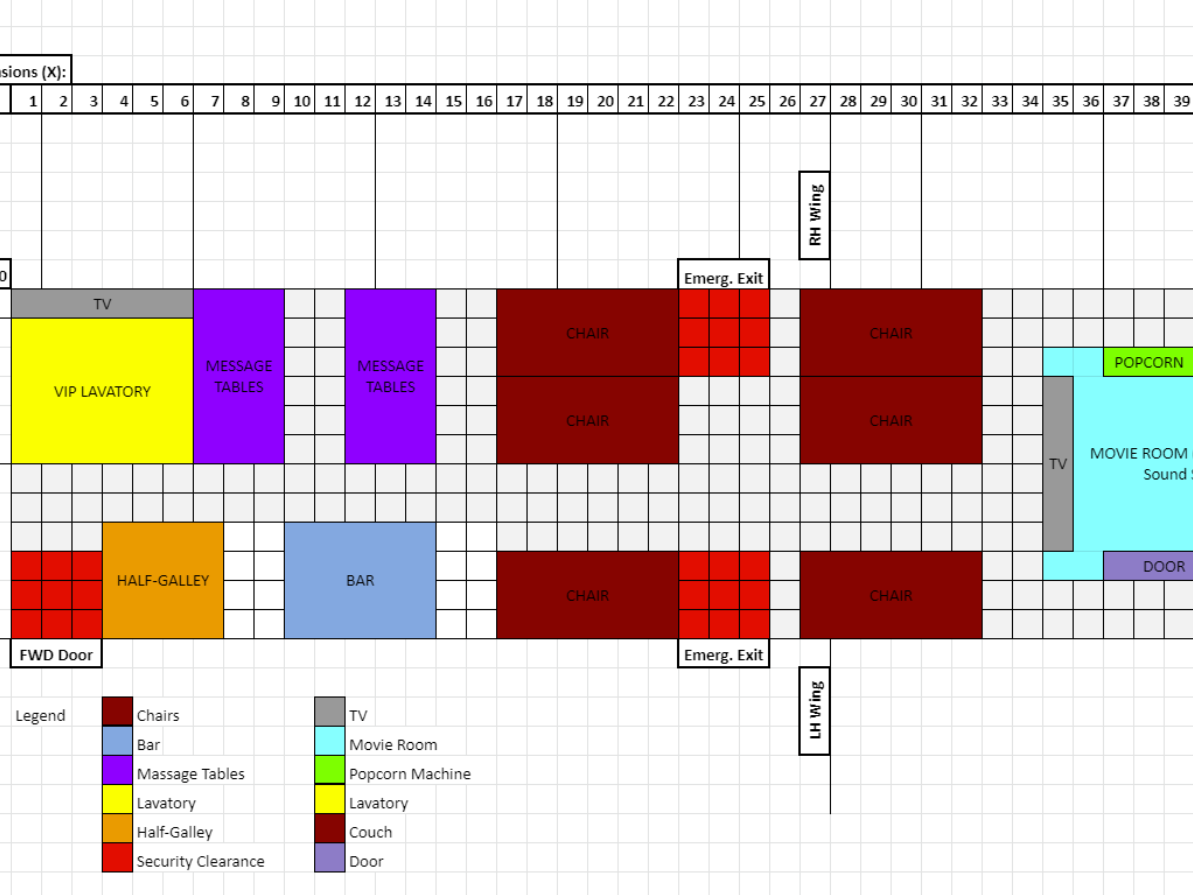

- Spearheaded the research and implementation of a MATLAB/Simulink based simulation ocean environment capable of predicting AUV controls behavior, sensor inputs (hydrophone, camera, etc.), and actuator outputs (motors, fins, etc.) under a realistic physics engine (gravity, buoyancy, lighting effects, water effects, etc.). Our team chose to use MATLAB/Simulink to build our simulation environment due to its flexibility in fitting our requirements and its ease of integration with SolidWorks for model generation and with Unreal Engine for environment creation.

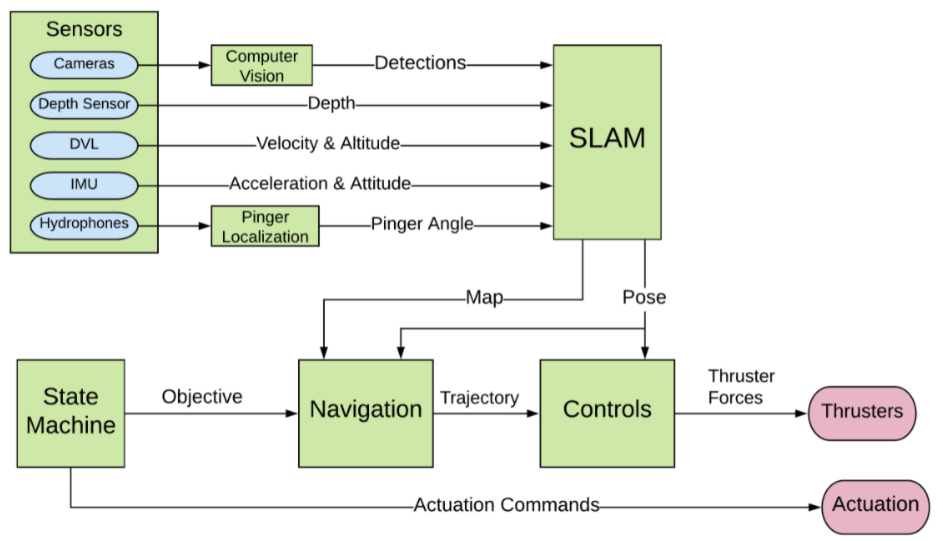

Planned ROS Architecture

- Analyzed and evaluated Robot Operating System (ROS) architecture from existing autonomous control designs, and used them as a starting point to develop an overarching systems architecture. We extensively studied existing ROS architectures both from other universities' AUV teams and from various published research articles. Using the information, we designed a systems architecture that satisfies our needs and requirements.

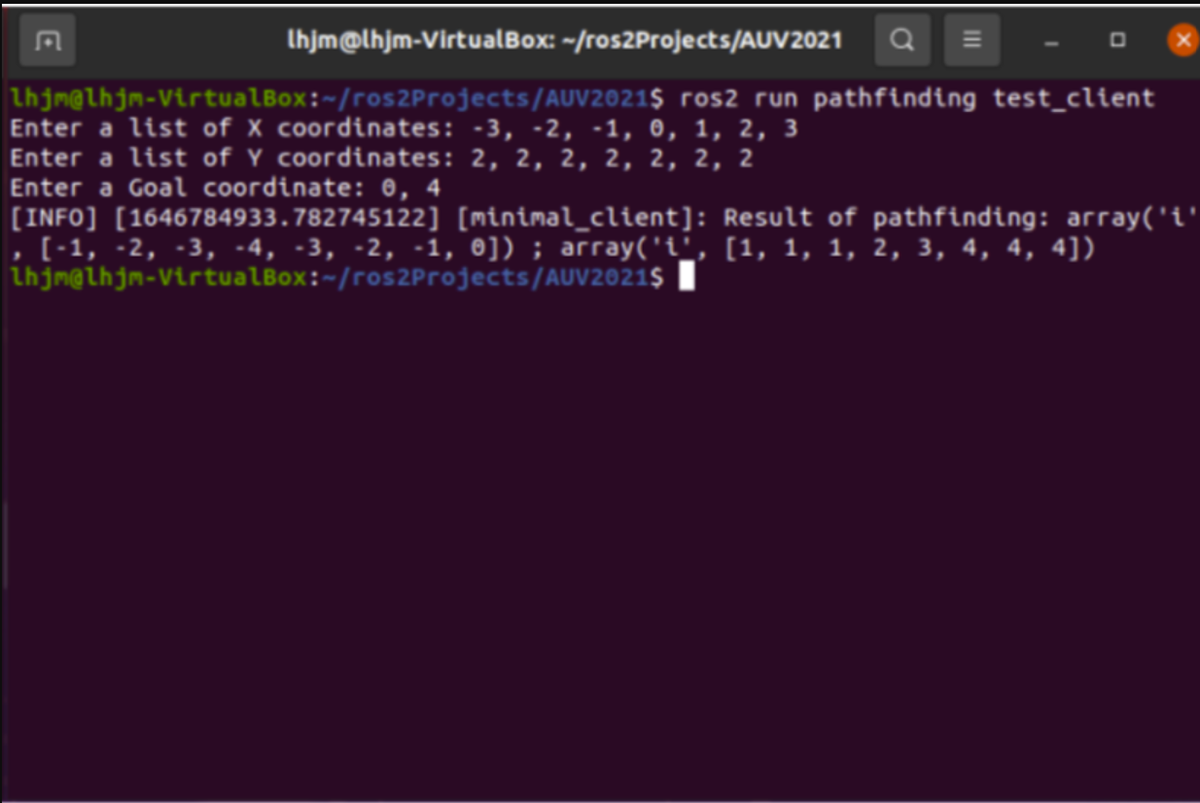

Basic 2D A* Testing Results

- Researched navigation and pathfinding algorithms, and assisted the implementation testing of the A* algorithm in ROS. Other algorithms researched include Dijkstra’s algorithm and the Backtracking algorithm. Both were determined to be less efficient than A* in 2D pathfinding. A* is then tested and implemented in ROS.

Sample YOLOv5 Results

- Annotated images used in the You Only Look Once (YOLOv5) machine-learned computer vision system. While object analysis through point detection and contour detection works, they only work reliably under narrowly controlled light levels and turbidity levels. Versions of YOLOv5 were tested to compare consistency in the unpredictable environmental conditions of real-life underwater applications. Since we did not have an available camera at the time, testing were done using screenshots of the Unreal underwater simulator that we built as well as opensource images provided by other universities.

- Documented every design decision and all the research material for knowledge transfer.

Outcomes

- Developed overarching architecture for autonomous operation through research and testing.

- Created the origins of an environmental simulator to virtually test AUV operation. Most of the imaging aspects are completed, and some physics still need to be added.

- Successfully implemented the computer vision system and used it to help the BUR ROV Competition team achieve 2nd place in the MATE ROV Regional Competition.

- Prepared to continue next year in implementation of these architecture and algorithms together with a physical AUV assembly.

2020 - 2021: Research Engineer for Remote-Operated Vehicle (ROV)

Overview

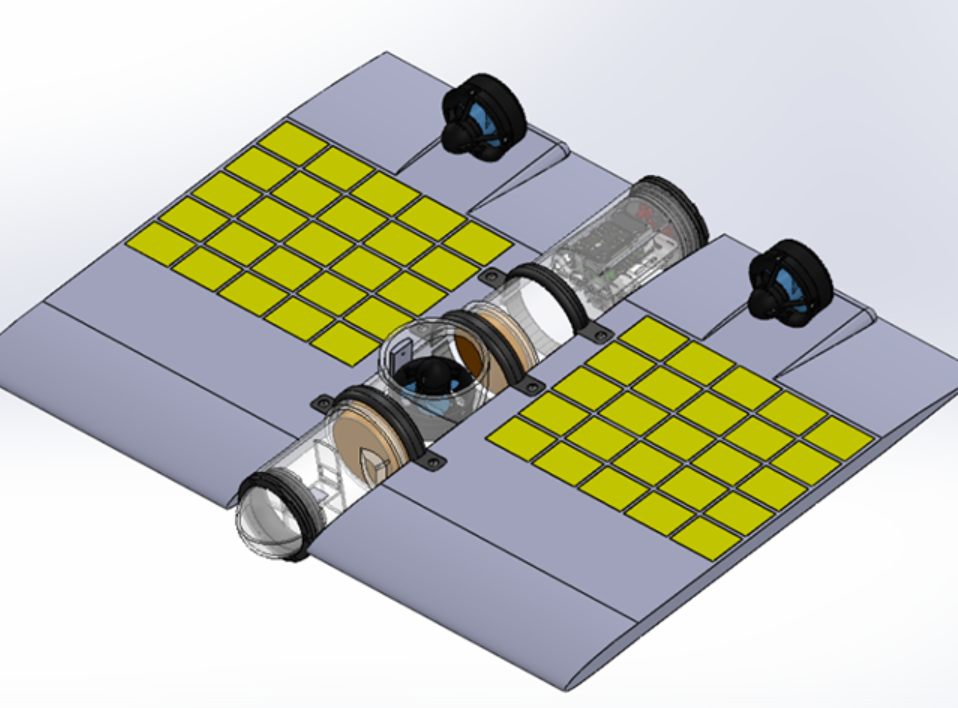

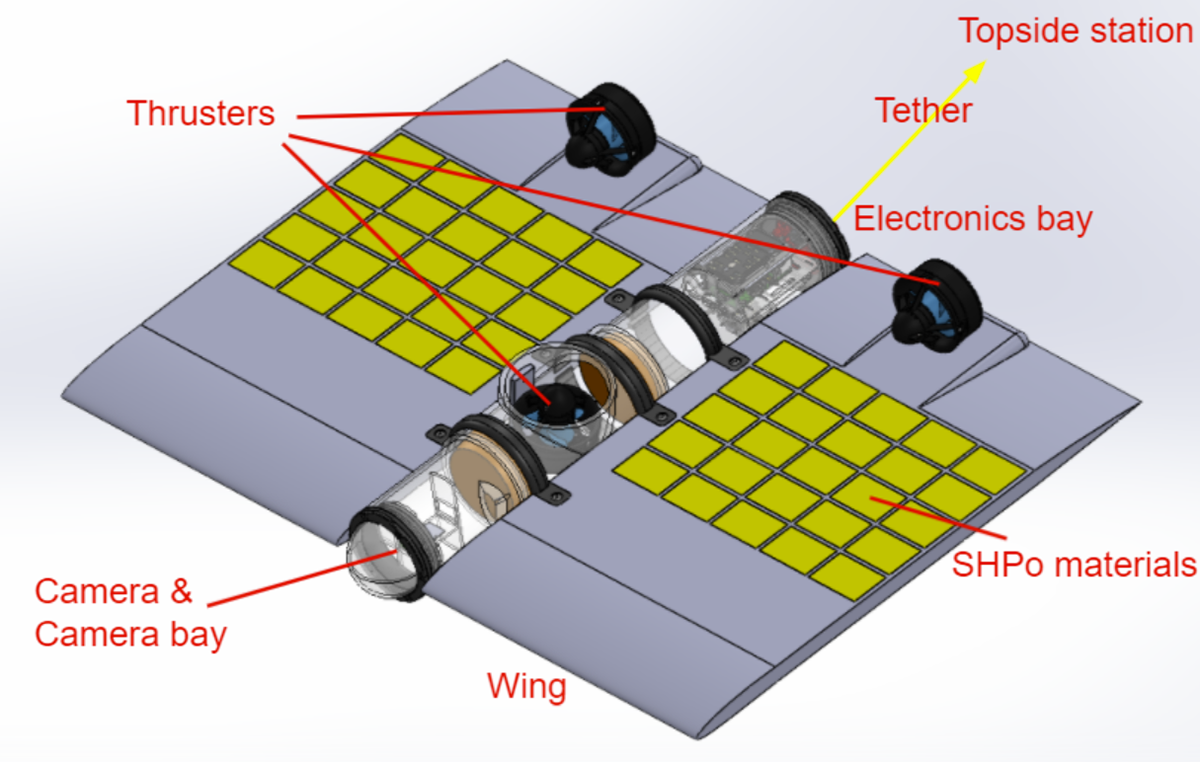

Bruin Underwater Robotics (BUR) was a new project created in 2020 that focuses on the development of Remotely-Operated Underwater Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs). The Research Team was a group of 10 engineers dedicating our design to test the effectiveness of the Super-Hydrophobic (SHPo) materials developed at Professor Kim's Micro and Nano Manufacturing Lab. While the material had been tested under a boat, Professor Kim wanted to test the material in a real-life application case such as an ROV.

Objectives

- At least 50% of the ROV surface shall be covered by the SHPo material.

- The SHPo material shall experience Reynolds Number of at least 3,000,000; turbulent flow.

- The speed of the ROV shall be compared with and without the SHPo material to estimate the effectiveness of the material in drag reduction.

- The ROV shall be manually navigated and tethered to the ground station, and shall be safe to operate underwater. This includes adequate waterproofing, power management, and propulsion.

Skills

Mechanical Design: SolidWorks

Simulation: SolidWorks FlowSim, ANSYS Fluent, CFD

Key Tasks

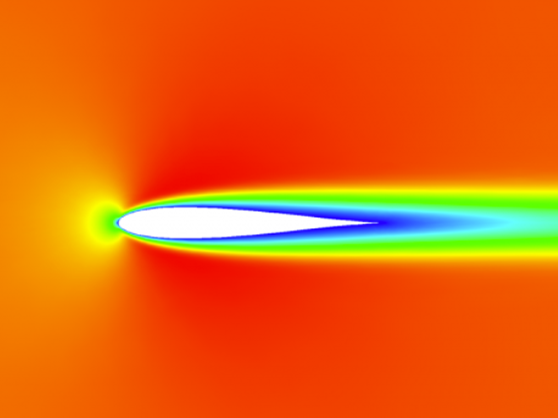

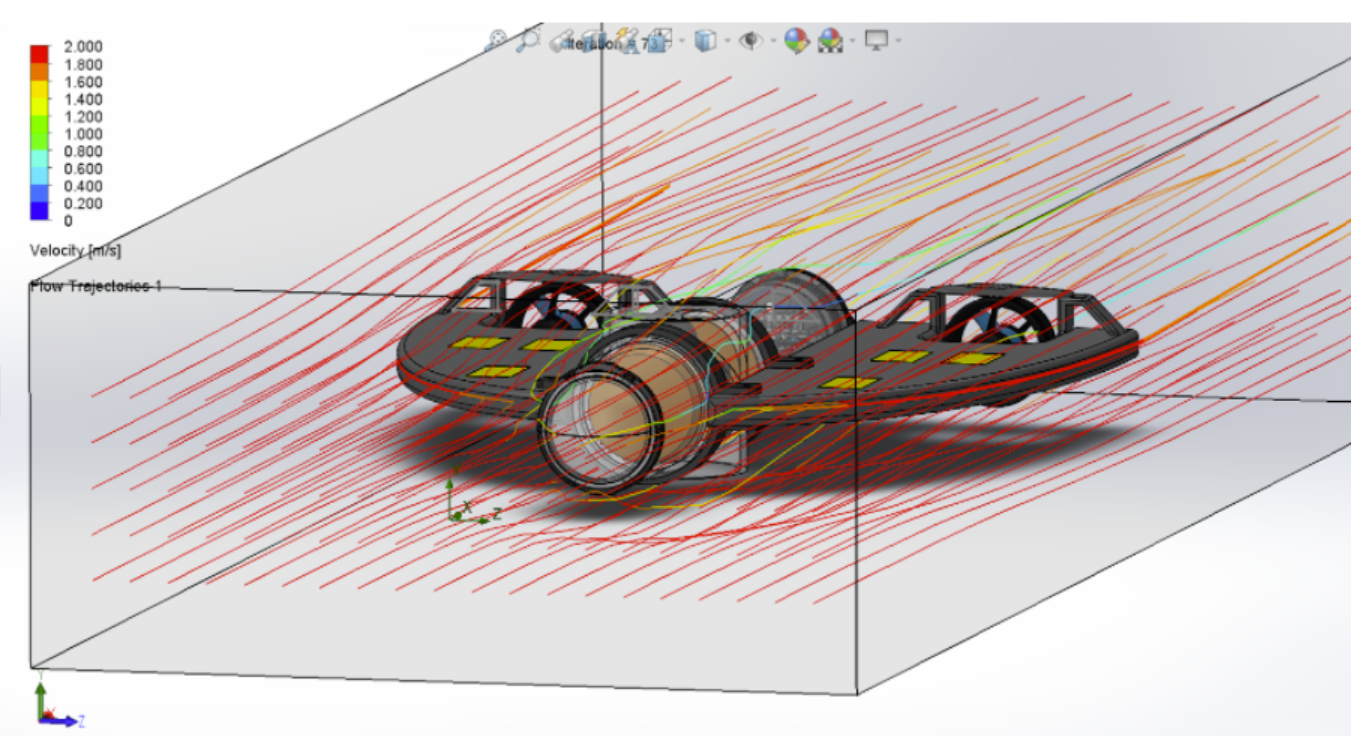

My key tasks involved running various CFD simulations for wing optimization and predict the Reynolds Number range.

SolidWorks FlowSim for Initial Wing Design

SolidWorks FlowSim Statistics for Initial Wing Design

ANSYS Fluent

- Thin symmetrical wings were selected to increase areas for SHPo material attachment, and they were planned to be 3D-printed in several pieces and glued together.

- A simplified CAD model of SPHongebob was first iteratively tested under the Flow Simulations of SolidWorks using pre-assumed cruising speeds and water conditions.

- The results from SolidWorks Flow Simulations were double checked against the CFD results from ANSYS Fluent.

- Cambered airfoils were also simulated to assist in lift/buoyancy generation, thus reducing the number of motors needed to control the ROV.

Outcomes

- Our final design, nicknamed "SHPongebob," had a length of 28 inches and a wingspan of 25 inches with room for 200 sq. inches of SHPo material, which cover about 50% of the total surface area.

- Majority of the SHPo materials was predicted to be in the acceptable Reynolds Number range. However, there were significant differences in expected Reynolds Number across the SolidWorks FlowSim and ANSYS Fluent estimations.

- The Micro and Nano Manufacturing Lab did not have enough manufacturing capacity to create the amount of SHPo materials we needed. Therefore, the project was halted before manufacturing and component testing.

- If budget permitted, more motors would have been added to ensure roll and pitch stability. At least 2 more motors would have been necessary.

- If more computational resources were available, I would have also liked to test the effects of having an acute or uneven leading edge on tripping the water flow to create higher Reynolds Numbers.

Links

BUR Website: https://www.asmebruins.com/bruin-underwater-robotics